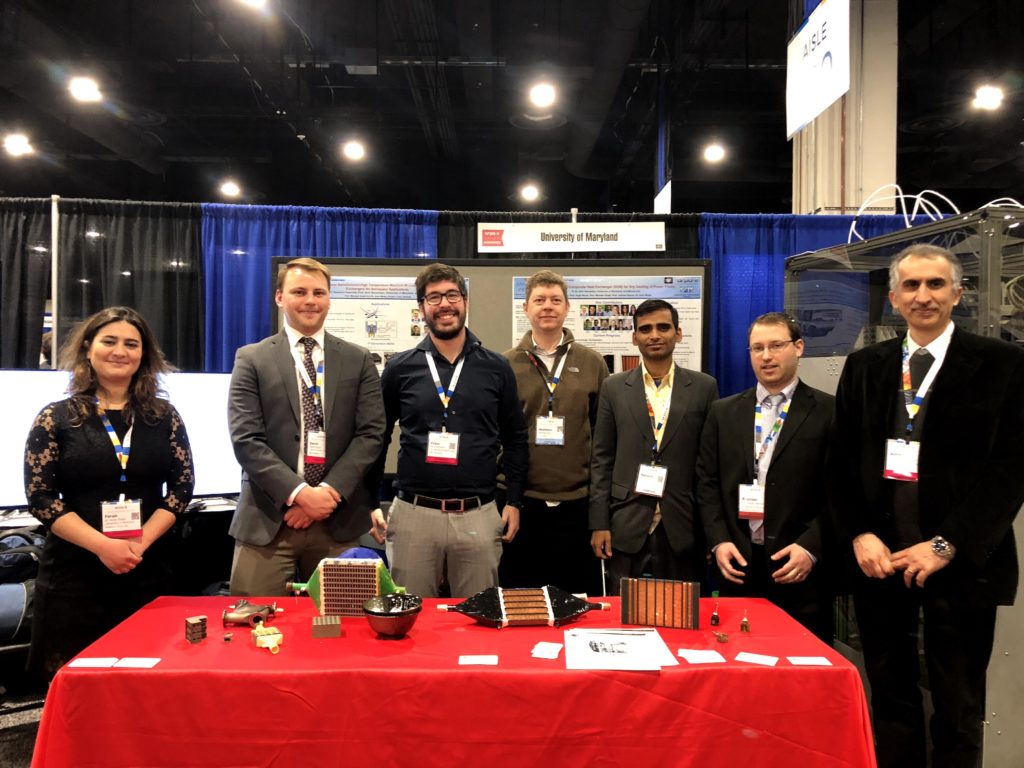

It is with great pride we announce that University of Maryland presented a Tech Demo in Energy Innovation Summit – ARPAE 2018 on “Additively Manufactured Record High Thermal Conductivity Polymer Composite Heat Exchanger” on Wednesday 5:00-5:15 p.m. in Technology Showcase, Evening session – Booth 830 in During ARPAE summit we had an interview in Voice of America about our CHX project.

Link : https://www.voanews.com/a/three-d-printing-heat-exchangers/4308249.html

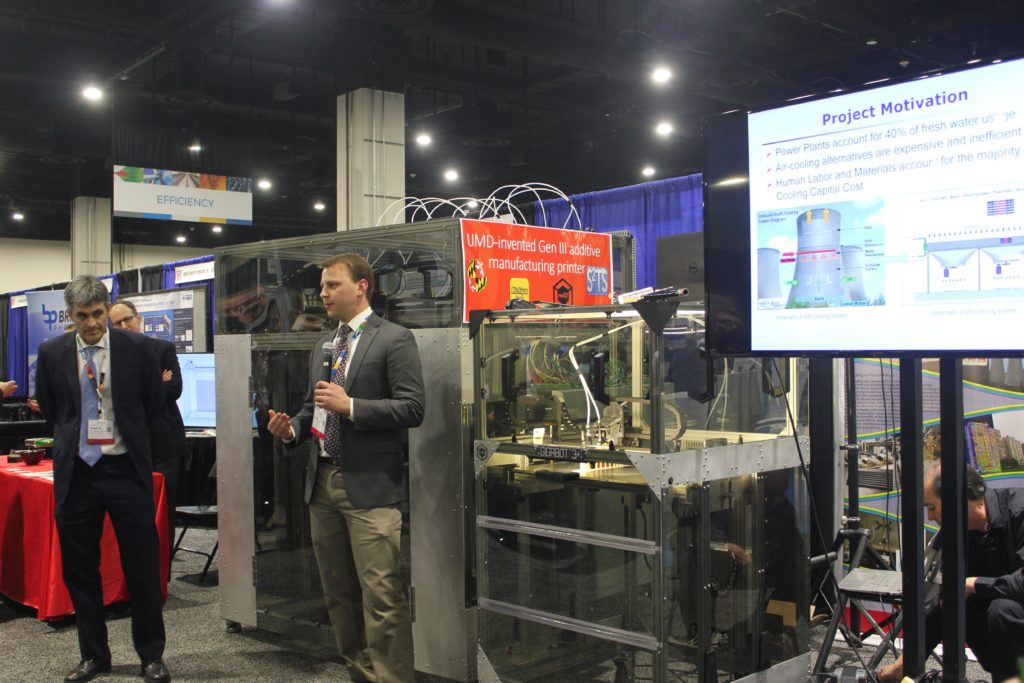

S2TS Laboratory at the University of Maryland, College Park, has successfully developed an innovative additive manufacturing technique for onsite (point of need) printing of industrial scale polymer composite heat exchangers for waste heat management of electricity generation thermo-mechanical power plants and diverse other thermal management applications. The project is sponsored By the U.S. department of Energy ARPAE division.

This project presents a novel Polymer Composite Heat Exchanger enabled by a Novel Additive Manufacturing technique to yield superior thermal performance at reduced pressure drops and with substantial weight reduction when compared to state of the art corresponding heat exchangers. The effective thermal conductivity of this polymer heat exchanger is ~115 W/(m-K) which is record high. The current design, generation III (Gen III) printer has a speed well over 200 times faster than its first generation (Gen I). Our future designs call for additional boost in the production speed. Developed with support from the ARPA-E ARID program, the heat exchanger technology has diverse thermal management applications and a demonstrated potential to introduce transformative changes to the way heat exchangers are designed and fabricated.

This novel additive manufacturing technique was invented at S2TS laboratory by Ph.D. student David Hymas, Dr. Serguei Dessiatoun and Dr. Michael Ohadi, and has been filed under International Patent Application Number PCT/US17/55521). The “heat exchanger has met and in most cases exceeded the performance metrics set by our sponsor,” said Dr. Farah Singer who is a member of the S2TS laboratory.